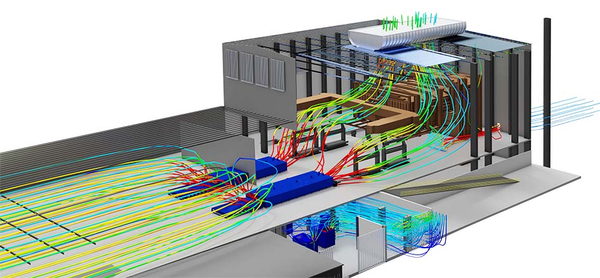

Computer simulation

tomorrow’s production has to meet high standards

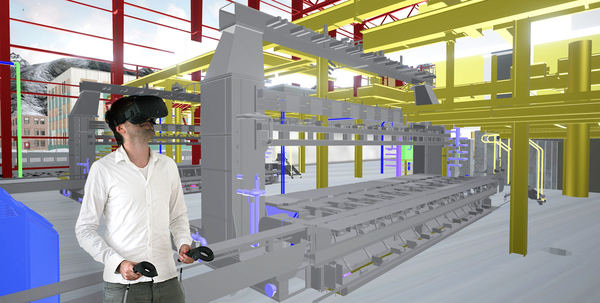

Virtual Reality

Efficiency and a safe future are as important for plant construction as cost savings and error reduction during the planning phase. The fourth industry revolution starts today with Industry 4.0. To meet these demands an investment in new technology is necessary. A technology that has the potential to give a positive impulse to plant construction in general and to the glass industry in particular. Precision and efficiency are indispensable from the start of a project, well before a glass plant is put into operation. In order to meet these requirements, cm.project.ing GmbH invests in the application of Virtual Reality (VR) and uses the possibilities of this technology regarding an efficient and future guaranteed layout planning for the glass industry.

Evolution of layout planning

When constructing a new glass plant, the investment is very high and each plant is unique and has to fit to the local and technical requirements of the site. The layout of a glass plant determines plant components, access, machines and equipment for years to come. A thorough layout is particularly important. VR is by no means a replacement for 2D and 3D planning, instead it has to be seen as an expansion of, and in addition to, existing planning steps towards an intelligent layout.

“Quality is improved and unplanned additional costs are reduced”

Minimal costs and errors

The more complicated a factory is and the more parties involved in the process, the more errors are likely to occur. Where multiple interfaces exist, errors are unavoidable. VR helps to locate and minimize errors at an early stage. It can detect weak spots in 3D models during layout planning. Inconveniently positioned equipment, pipes, instruments or valves that are hard to reach.

“VR involves the whole project team and the planning process profits from the cross exchange of experiences”

Simulation of future events

In a virtual model, future works processes such as production or maintenance can be simulated. The staff can adapt and be trained virtually for their new work place. During the planning, process adjustments and changes can be made in the model to create a well thought-out layout concept which is submitted to virtual testing in all aspects. Only if the planned factory has passed the practical test is it ready for the real execution.